You can create an indoor porch by simply installing the front wall in the second or third roof truss. You could do the same with the rear wall of course.

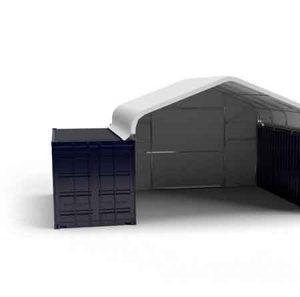

Container

Shelters

From €690

Temporary storage

or work space in

an instant

You can create an indoor porch by simply installing the front wall in the second or third roof truss. You could do the same with the rear wall of course.

Our storage buildings are delivered without an electric opener as standard. Optionally you can order an electric opener (including 2 remote controls) for the roll-up or overhead door

Kroftman storage buildings can always be placed without a foundation. This distinctive advantage allows you to achieve huge savings on the overall project costs. This allows one to place a storage building much more quickly and inexpensively. The storage building can also be placed on Stelcon® sheets, asphalt, pavement and even on compacted earth, gravel or rubble.

Have a look at our special page about the anchoring options.

Kroftman only supplies storage buildings without windows. If you nevertheless would like to place one or more windows in your storage building, you must do this yourself. In that case, keep in mind that the structural calculation is no longer applicable and the warranty on the construction and sheeting will then lapse.

Yes. You’ll then receive extra sheet material to close the door opening.

If you wish to reduce extreme temperatures or condensation you can insulate your building yourself. This is done by installing common insulating panels (such as sandwich panels, Polystyrene, EPS, PIR, Styrodur®, Isover® or Fastfixx®) tightly between the truss tubes. The seams should be sealed with insulation tape or caulking. Ideally the insulation panel thickness should equal the depth of the tubes; 75mm or 50mm. (see construction drawings) Due to the remaining thermal bridges and uninsulated roll-up door/skylights these buildings are less suitable for full heating. Please be aware that the maximum snow load allowance should be reduced with the weight of the roof insulation.

With the E500 series it is possible to build in a different size of roll-up door. We then deliver the entire storage building without a roll-up door so you can order a roll-up door with the desired dimensions yourself.

Due to a different steel construction, it is not possible to install a wider roll-up of overhead door with the H600-, H700h-, H800h- and H900-series storage buildings.

Do you want to build in a higher roll-up or overhead door? Then you need to build the storage building on a stem wall to enlarge the opening for the industrial door.

Yes. To calculate the maximum snow load, you have to subtract the weight of the solar panels from the snow load.

Example: if the snow load for the storage building in question is 1,2kN/m², then the roof can withstand 120 kilos of snow per square meter.

If the solar panels for example weigh 40kg, 80kg remain. In a region where the snow load is less than 0,8kN/m² (80kg per square meter), the storage building can be equipped with solar panels.

Dripstop® is a felt layer attached by default to the roof sheets of the non-insulated H-series storage buildings. It ensures that valuable goods and materials remain dry, even in case of condensation.

Moisture appears when the outside temperature drops and the inside temperature remains relatively high. The Dripstop® felt layer absorbs the moisture and releases it when the outside temperature rises, after which the damp evaporates. This prevents moisture dripping down from the steel roof and damaging the stored goods.

Explanation about how Dripstop® works

Comparison between a roof with and without Dripstop®

The non-insulated storage buildings ventilate at the front and rear under the ridge cap and the gable trim. In addition, all roof seals are equipped with ventilating foam tape. However, the ventilation is not calculated.

The insulated storage buildings have no ventilation openings. You can optionally have a natural or mechanical ventilation system installed.

Ventilation standards are not necessary for storage buildings unless the application prescribes these (for instance storing chemicals).

Yes. You will then receive extra sheet material to seal the opening at the front. Note that the height of the industrial door in a side wall is lower than in a front or back wall.

You can, but the warranty will then lapse. The sheet material has a polyester top coating. If this is covered by an extra layer of paint, the coating no longer offers full protection.

For the H-series, the man door can effortlessly be placed to the left or the right of the roll-up door. And rotating clockwise or counter clockwise.

For the E-series, the man door can only be placed to the right of the roll-up door.

Installation video for a Janus roll-up door (only applicable for non-insulated storage buildings)

Installation video for a Novoferm (Alpha) T450 overhead door for the front/back wall

Installation video for a Novoferm (Alpha) T240 overhead door for the side wall

No, the laws and regulations prescribe that there must be at least 100 cm between them. A distance of one (non-insulated) or two (insulated) meter is also necessary for assembly.

The storage buildings meet the performance requirements for the fire safety of storage buildings as referred to in the Dutch Building Decree 2003. This means that in the event of a fire, the structure remains intact long enough for it not to collapse prematurely. If you want to increase fire safety for people and materials, we advise you to equip the storage building with a sprinkler system.

This is possible for the H-type storage buildings. You can select this as an option. If necessary, you will receive additional construction drawings. Depending on the size of the storage building the additional man door and / or industrial doors can be installed in the rear wall or in the side walls.

No additional man doors and / or industrial doors can be ordered for the E-series.

All man doors are equipped with a cylinder lock. The roll-up doors have a latch for a padlock (not included). The overhead doors can only be opened manually from the inside. The storage buildings can therefore be entirely closed up.

In the product specifications you will find the maximum wind and snow load as described in the official structural calculations. We recommend that you only place the product in wind and snow zones that do not exceed these standards. If you nevertheless choose to install the storage building or tent in a region with higher maximum wind and snow loads, please bear in mind that this is at your own risk.

All our storage buildings can be extended indefinitely with a multiple of 3.0 (E500 storage buildings), 2.7 (H600, H700h and H800h storage buildings) or 3.3 meters (H900-H1000-H1100-H1200 storage buildings). The E500 storage buildings can easily be adjusted to the desired size during assembly by shortening all horizontal parts between the last two frames. The shortest length can also be shortened in this way. The H600, H700h, H800h, H900, H1000, H1100, H1200 series storage buildings cannot be shortened.

The width of the storage building cannot be increased or decreased.

By default, the storage buildings are supplied without gutters and drainpipes. You can optionally order the matching drainage system. The Kroftman drainage system for storage buildings is entirely made of galvanised sheet steel. The system consists of drain pipes on both sides of the storage building with upright pipes (plus final bend) down to the ground. The capacity of the gutter and the number of upright pipes is tailored to the size of the storage building. The standard available colours are pearl-light grey (RAL9022) and anthracite grey (RAL7016).

The main difference is that a roll-up door is made of continuous steel sheeting and an overhead door consists of hollow aluminum segments filled with insulating PUR foam. This means that with an insulated storage building only an overhead door is possible. With an non-insulated storage building you choose from both.

Overhead door

+ Insulated

+ Opens complete, so full height to use

+ In the event of damage, only the damaged element needs to be replaced

+ Makes less noise

+ Burglary resistant: can only be opened manually from the inside

– Can not be opened from outside (except with a remote control)

– More expensive

– The overhead door hangs horizontally in the indoor area, so that the working height in the storage building cannot be fully used

Please check also our Q&A about how to install a roll-up or overhead door

Of all our storage buildings, storage tents and container shelters we have structural calculations available in German. These are available on request and free of charge.

For these structural calculations we work with German engineers. These structural calculations always meet the ′Eurocode′ standard supplemented by German codes DIN+DIBt ensuring wide European and International acceptance. To maintain the legal status, we only provide the original untranslated documents in the German language. Should this cause you any difficulties, you can use these documents as a basis to ask a local engineer to draw up a structural calculation in your own language which meets your local requirements.

That depends on the product and the local regulations. A permit is usually not necessary for temporary placement. For (semi) permanent placements, it’s best to contact your municipality.

You can download the construction drawings to apply for a building permit. Upon request we can also supply the structural calculations entirely free of charge and obligation.

The transport volume of an insulated storage building is 3 to 4 times greater than that of a non-insulated storage building. The insulated sheeting is 4 cm thick, that of non-insulated sheeting is only 0.4 mm thick. The skylight panels of a non-insulated storage building are also much thicker than those of an non-insulated storage building. The insulated storage building has an insulated overhead door as standard. This door takes up much more volume than the standard roll-up door of an uninsulated storage building. Due to the larger volume, we cannot combine the transport of the warehouse with the transport of other products. This means that we must arrange transport for just one address. As a rule, this is always more expensive than a combined transport.

To guarantee fast and trouble-free assembly, we make the inspection and assembly conditions mandatory for customers who have the product assembled by our own assembly team. However, the instructions mentioned in the document naturally also apply to do-it-yourself assembly. We strongly advise you to follow this so that you will not be faced with any surprises during assembly.