Storage buildings

8 tips to keep the temperature stable in your storage building

8 min reading time

At Kroftman, we have been selling storage tents, storage buildings, and container shelters for 15 years now. We have completed nearly 13,000 projects worldwide. Sometimes, however, problems may arise with a storage building. In this blog, we have listed the five most common problems with an already built storage building for you, along with how to solve these problems.

Problem 1: Water is leaking under my roll-up or overhead door.

Problem 2: The electric motor is not working properly.

Problem 3: The cable of the overhead door comes off when using the electric motor.

Problem 4: My roll-up or overhead door won't close anymore.

Problem 5: My storage building is showing signs of early rusting.

For a pedestrian door

This problem can only occur with a pedestrian door if the door, finish, or threshold is not correctly installed or sealed. The solution to the problem lies in correcting this error.

For a roll-up or overhead door

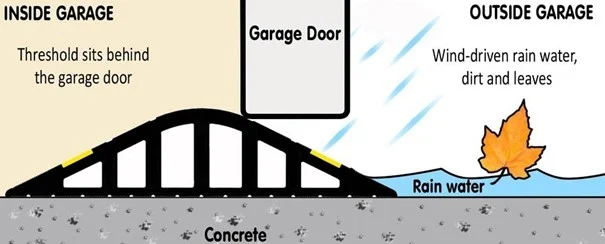

With a roll-up or overhead door, water can enter under the door when the storage building is placed on paving or another, not completely flat surface. The problem is that the rubber under the door does not form a watertight seal with the ground. This is further exacerbated if the ground is not perfectly horizontal.

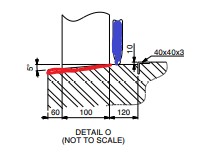

Our advice in such situations is to install a water barrier on the inside of the door, such as the ones available on this website. Kroftman does not sell these themselves. The water barrier is designed to create a watertight seal between the door and the floor. The diagram below illustrates this well. With this, your problem is hopefully solved. It is important, however, that the slope of the ground on which the storage building stands does not slope towards the door. Otherwise, it's literally mopping with the tap open.

As a preventive measure for a concrete foundation, we recommend, if you have a concrete foundation made, to create a recess in the foundation at the location of the door, with a sloping runoff to the outside. Below is an image of this detail. Blue represents the door on the inside of the storage building. The red line represents the sloping runoff to the outside. This image is described in the construction drawing.

The door stops opening

Most problems with the electric motor not functioning correctly are related to an overhead door that has been incorrectly installed. If the door runs too heavily, for example due to lack of lubrication or incorrect adjustment of the springs, the motor will detect this and stop as a safety precaution. This is to protect both the mechanism and because the motor has a pinch detection as a safety feature. If the motor starts to run heavier, it could mean that something or someone is stuck. For safety reasons, the motor will then stop. Depending on the situation, it may also retract the door a bit. If after lubrication and proper adjustment of the springs the motor still gives problems, you can calibrate the motor. You do this using a number of buttons on the electric motor. The exact procedure for this is described in the manual of the electric motor. The motor will then take the fact that the door runs heavier as standard and will not stop anymore. Problem solved!

The emergency release has been pulled:

If the door is equipped with an electric motor, it cannot be operated manually. In emergencies, such as a fire or power outage, it must be possible to open the door manually. For this purpose, the motor has an emergency release in the form of a red cord. If you pull on this, the electric motor is disengaged from the door and you can open the door manually. Sometimes someone accidentally pulls on this emergency release. To re-engage the electric motor with the door, simply pull on the emergency release again. Now the motor should work again. Depending on the situation, it may be necessary to recalibrate the motor after this. You can read how to calibrate the motor in the manual.

Preventive measures to prevent these problems

To prevent problems, it is crucial that the roll-up and overhead doors are installed correctly. Building the storage building itself can be done by technically skilled individuals. Installing, especially, an overhead door requires specialized knowledge. We have instructional videos that show you how to install an overhead door. Legally, you must have an electrically operated industrial door installed by a specialist and the door must be inspected annually. That is also the reason why you receive a sticker with the door that you stick on the door after assembly, with the date of the next inspection (1 year after installation). After each inspection, a new sticker is placed on the door. If you don't do this, no one will likely check it. However, if an accident occurs with this door because it is not properly maintained, you will be liable. The same applies to our warranty conditions for the door and electric motor. These remain valid only with correct installation and annual maintenance of the door and motor.

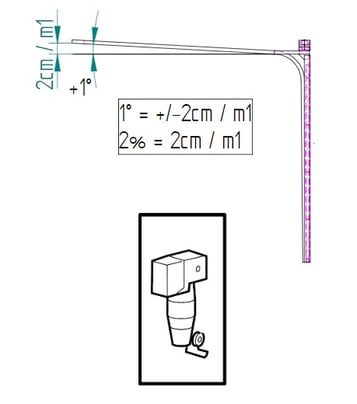

This problem is almost always caused by incorrect installation of the overhead door or, in exceptional cases, by a door being blocked by an obstruction. In that case, it is necessary to remove this obstruction. With incorrect installation, we mean, for example, the installation of the rails. When the motor tries to lower the door, the door must roll downwards through the rails due to its own weight. If the rails are not mounted sufficiently downhill or even uphill, the door will not roll down. In that case, the motor will unwind the cable, but because the door does not descend, the cable will come loose from the drum. If the user does not intervene in time, the door may later fall down until the cable is taut again, with all the consequences that entails.

To solve this problem, you will need to check the manual to see if you have mounted the rails correctly. In the diagram below from our manual, you can see that when using an electric motor, the rails should run 1˚ upward. That's about 2 cm per meter. For a 4-meter rail, that's 8 cm in total at the end. With manual operation, this is the other way around, and the rails should run 1˚ downward. Applying the correct 'slope' of the rails will prevent this problem.

We sometimes receive questions from customers about why their door no longer (completely) closes. Without more information, it is not possible to answer what the reason for this problem might be. There is no one common cause to name. In that case, we ask you to email us photos or videos so that our engineers can look along with you. They will then provide you with an answer to what you can do about this problem.

The structure of our storage buildings (the c-profiles) is made of galvanized material and cut to size during production. Due to cutting, the 'cut edges' lose their protective layer against rust formation (the galvanic protective zinc layer). Therefore, these ends may show signs of rust formation over time. You don't have to worry about this, as it will not rust further due to the galvanic protection of the zinc layer on the rest of the profile. The same applies to some mounting brackets.

Sheet metal cladding of the storage building may also show signs of early rusting. The problem often arises because the protective layer has been damaged by a small injury during use or during assembly. Advice is to treat early rusting here with a 1-component metal paint. It's the same paint used for cars. If you want the paint in the same color as your storage building, make sure the paint has the same RAL color number as the RAL color of your storage building. You can also use clear paint, but you will still see the rust. This is not the case with colored paint.

In any case, you don't have to worry about rusting through. Kroftman offers a 10-year prorated warranty against rusting and excessive discoloration on the cladding and guttering. On the steel structure, we offer a 10-year prorated warranty against rusting. We understand that a rust spot is not a nice sight. Therefore, another tip for rust prevention. If you are going to grind near the storage building, metal sparks can hit the sheet metal of the storage building and burn a hole in the paint. This damage causes you to lose the protective paint layer there, and rust may occur. Therefore, always keep a sufficient distance from the storage building during work to prevent damage.

You can find more information about our warranty conditions on our website under the 'Specifications' tab for each type of storage building. If you have already purchased a stotrage building from Kroftman and encounter problems, please feel free to contact us. We are happy to help you find a solution.

We hope the above information helps you make an informed decision. If you want to know exactly what the storage building of your choice costs, please fill out our quotation tool without obligation. At the last question, enter your zip code. We need your zip code to calculate the shipping costs. You will receive the login details to view your quote by email. You can see on the quote at a glance what your shed costs, including shipping costs. You can create multiple quotes and select different options. This way, you can compare them well.

Do you still have questions? We are happy to assist you further.