Storage buildings

8 tips to keep the temperature stable in your storage building

8 min reading time

Are you curious about the components and materials of our self-build storage building? At Kroftman, our engineers design the storage buildings themselves. Since it's a self-build storage buildings, they have carefully considered each component. There are parts and materials that we purchase (worldwide) and parts that we manufacture ourselves. In this article, we will tell you more about the following ten components of our self-build storage building:

1. The C-profiles

2. The brackets

3. Bolts & nuts

4. Anchor bolts & ground pegs

5. Wind bracings

6. Sheet material

7. The finishing profiles (trimming)

8. The doors & electric motor

9. Gutters and downspouts

10. Sealing material

Before we zoom in on the ten components, we would like to briefly discuss the two different types of self-build storage buildings that Kroftman sells. We have the E-series storage buildings and the H-series storage buildings. The E-series storage buildings are competitively priced, making them cheaper than a warehouse tent. You can already get an E-series storage building from €10,500. These are the storage buildings that we purchase in their entirety, in large quantities, and do not produce ourselves. You cannot make any modifications to the storage building. It comes standard with a walk-in door and a roller door. The only options we offer for the E-series storage buildings are:

In this blog, we focus on the components of the H-series storage buildings and not those of the E-series storage buildings.

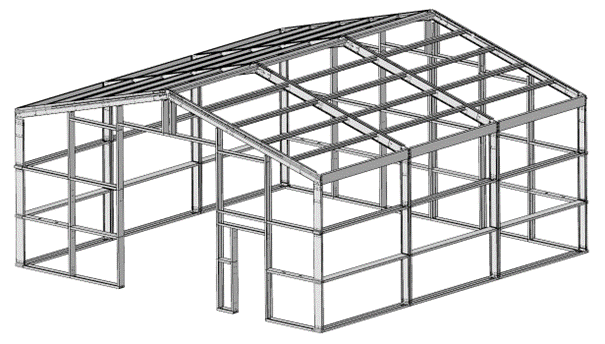

The construction of our self-build storage building consists of so-called C-profiles. These are long metal beams made of sheet material with folded edges. This gives the cross-section of the beam the shape of the letter C, as seen in the photo below.

By bending the sheet material into a C-shape, our construction remains light but sturdy. All beams of the construction are made according to the principle of a C-profile. We use them for:

The C-profiles are developed for their position in the construction. They differ in length, width, and height and have a different hole pattern.

We manufacture the C-profiles ourselves. This has the advantage that we deliver a consistent quality, the parts always have the correct dimensions, and a fast delivery time is guaranteed. We make the C-profiles from certified sheet material that comes in a roll. The certification of the sheet material stands for reliability and that the material meets the required strength. We unroll the sheet material and punch holes in it at the desired locations. Then we cut the sheet material to the correct length and width and fold the edges to give strength to the beams. This creates the characteristic C-shape.

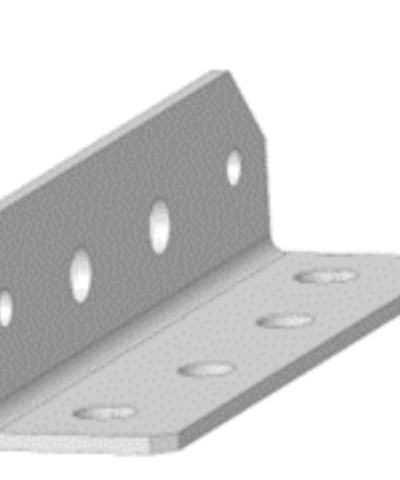

The C-profiles are connected to each other by means of metal brackets. The hole pattern in the bracket corresponds to the hole pattern of the C-profiles. The brackets are also made by us from laser-cut plates (with hole pattern) that we fold 90 degrees. We do this ourselves so that we can guarantee a consistent quality and always have these brackets in stock. Below is an example of a bracket.

The brackets for connecting the C-profiles are secured with bolts and nuts. Once fastened, you have the construction as shown in figure 2. We purchase the bolts and nuts when the order for the storage building comes in.

The storage building is anchored to the ground via the base rail, depending on the type of surface, with ground pegs or anchor bolts. In the overview below, you can see when you use ground pegs and when you use anchor bolts. You can read more about this in this blog.

| Ground type | Anchoring by means of |

| Concrete foundation | Anchor bolts |

| Concrete slabs (Stelcon slabs) | Anchor bolts |

| Anchoring on hard surfaces such as paving, asphalt, or compacted sand/gravel soil | Ground pegs |

The dimensions of the ground pegs and anchor bolts vary per type of storage building. We purchase these parts and always have them in stock.

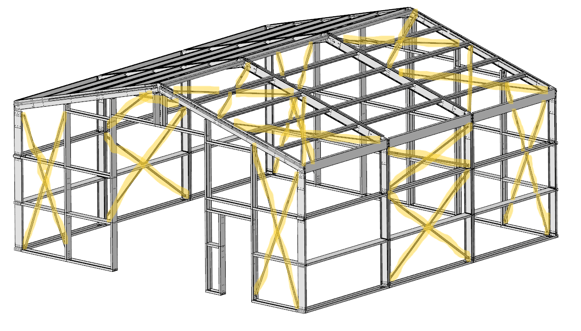

A storage building is a rectangular 'box' and lacks sufficient strength in this form. To create strength, you install wind braces in a cross shape. This ensures the stability of the storage building. These wind braces are installed in the side, front, and back walls, as well as in the roof. Depending on the size of the storage building, multiple wind braces are installed. In the diagram below, you can see the construction of the storage building with the yellow-highlighted wind braces in a cross shape.

Wind braces

In the roof, the wind braces are located in the first and last segment (or bay). In the front and back walls, the wind braces are in the left and right segments. For smaller storage buildings, one wind brace in the front and back walls is sufficient. For longer storage buildings, additional wind braces are added to the side walls to ensure stability. For smaller storage buildings, we use steel cables as wind braces, and for larger storage buildings, we use metal strips. We purchase the steel cables, and we manufacture the metal strips ourselves.

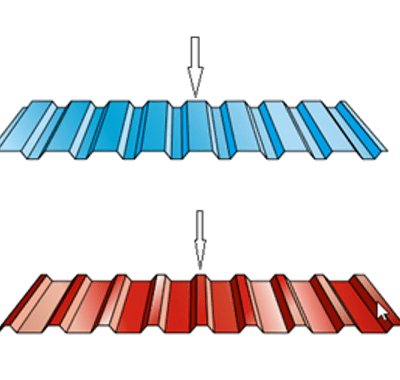

The construction of the storage building is covered with sheet material. You have the choice between uninsulated and insulated sheet material:

All sheet material is purchased from suppliers in the Netherlands.

The finishing profiles, also called trim, are galvanized steel plates with a 25mu (micrometer) polyester coating. We use these to finish the corners of the storage building. You can choose from eight different colors for the finishing profiles. We purchase the finishing profiles from an external supplier.

All our storage buildings come standard with a metal walk-in door and an overhead door. Only the uninsulated storage buildings in low configuration (height 30 and 33) come standard with a roller door. For an additional fee, you can still choose an overhead door if that is your preference. You can add an electric motor to your roller or overhead door. You will need electricity in your storage building for this. You will have to install this yourself. We purchase all doors and the electric motor from external suppliers.

Our storage buildings are delivered as standard without gutters and downspouts. This does not cause any problems; rainwater will run down along the side walls. If you prefer the rainwater to run into the ground at one specific location, you can order our matching drainage system made of galvanized metal as an option. We purchase the gutters and downspouts from elsewhere and they come in two different colors for you to choose from.

We provide standard Butyl tape with every storage building. This is a self-adhesive strip made of butyl rubber. You can place this between the base rail and the foundation to prevent water from entering the storage building. If you build on a concrete foundation with the correct dimensions, a water barrier will prevent water from getting under the base rail. However, if you build on cobblestones, achieving a waterproof connection of the storage building is difficult. To prevent as much as possible water from entering the storage building under the base rail, you can use Butyl tape. If you wish, we also provide a cartridge with Tixophalte. This is a sealing compound based on a special rubber-bitumen mixture. With this, you can seal any gaps in your warehouse and apply an extra layer under the base rail, in addition to the Butyl tape. Be aware that water can always find a way to get in somewhere. By applying Tixophalte or Butyl tape, you can reduce the risk and/or the amount of water entering the storage building.

We hope the above information helps you make an informed choice. If you want to know exactly what the storage building of your choice costs, please feel free to fill in our quotation tool. From this, you will receive a quotation by email, showing at a glance what the costs and transport costs are for your storage building. You can create multiple quotations and select different options to compare them thoroughly.

If you still have questions, we are happy to assist further.