Inspection Conditions

Downloads assembly conditions

Downloads inspection conditions

- The first building inspection is at the expense of Kroftman;

- A building inspection is planned on indication, read readiness, of the client;

- For the building inspection to be approved the requirements, as stated below, must be met (substrate, work, labor and site facilities) (construction ready);

- If the building site, after arrival of the building inspector, still is not found ready by the building inspector or by Kroftman, then it is possible that a re-inspection must take place at the expense of the client;

- The costs (€ 500,-) for a re-inspection are for the customer;

- Kroftman will only make an assembly appointment after approval of the building inspection;

- The assembly appointment will take place at least 4 weeks after the approved building inspection.

Substrate:

|

Dimensioned construction drawing page 3. |

|

Dimensioned construction drawing page 4. |

|

Unevenness maximum of 5 millimeters. |

|

Gradient maximum of 1 centimeter per meter. |

Work facilities:

|

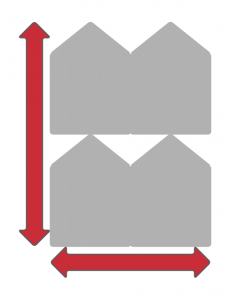

2 times the area of the hall + 2 times the height of the hall in free movement space. |

|

1 meter clear around the hall with a level surface. |

|

Unloading area no more than 10 meters away from the construction site. |

Labor provisions:

|

16 Amps. |

|

Toilet, water. |

Supply & disposal facilities

- Indicated location for waste.

- Indicated location for electricity.

- Indicated location for unloading.

- Indicated location for rental equipment.

Assembly Conditions

Kroftman inspects a construction site before the assembly work starts. Therefore clear agreements are important to avoid delays or additional costs.

For assembly of a Kroftman product by a Kroftman assembly team the following conditions therefore apply, unless explicitly agreed otherwise.

Article 1: General

- Kroftman shall accept an assembly order only after the building site has been finally approved after a building inspection. From this Kroftman can conclude that all conditions mentioned below are fulfilled. Possible deviations from these inspection conditions have to be demonstrably remedied before the assembly can start.

- The client shall provide a forklift truck (lifting capacity 1500kg) with driver at the unloading point, at the agreed delivery time, to unload the goods immediately.

- At the end of the last assembly day, an authorized employee of the client must be present for the delivery and any (final) payment.

- Any final payment must be made by bank transfer on the last day of assembly. The bank transfer receipt shall be handed over to the Kroftman Assembly Manager at the construction site before leaving the construction site. The client becomes the owner after signing the delivery form and full payment. After that the client is entitled to use the product.

- Assembly waste and packing material will be carefully collected and stacked by the assembly team for disposal by the client.

- In case of stormy weather or a temperature below 5 ̊C assembly will not be started or all ongoing assembly work will be stopped. Kroftman shall, if necessary, schedule a new assembly appointment.

- Client is responsible for all necessary permits and documents. This may include, but is not limited to, a building permit or site-specific strength calculations.

- The slope of rain gutters will always follow the slope of the site.

Article 2: The unloading point

- The unloading point must be easily accessible, irrespective of the weather situation, for lorries up to 46 tonnes in size (l x w x h) with a maximum ground clearance of 0.3m.

- The unloading point must not be further than 10m from the construction site.

- The unloading point and the road to the building site must be easily passable with a forklift or Kooiaap regardless of the weather situation.

- The unloading point must be accessible at the agreed time of delivery and adequately closed by the principal.

Article 3: The building site

- A working space of at least 1 metre must be kept clear around the construction area.

- The building area and the surrounding free work space must be easily accessible and passable for light commercial vehicles, forklift trucks, mobile scaffolds, aerial work platforms and telescopic handlers, irrespective of the weather conditions.

- A 220V(16A) electrical connection must be available within 10m of the construction site.

- The Kroftman mechanics should have access to the building site from 08:00 till 17:00 during working days.

- The Kroftman mechanics should have access to sanitary facilities.

Article 4: Supplementary conditions for Kroftman buildings

For assembly with concrete anchors on a concrete foundation

- The concrete foundations, as determined by Kroftman (concrete ring or concrete slab), for the sheds must be manufactured with the exact surface dimensions according to the Kroftman construction drawings.

- The concrete foundations (concrete ring or concrete slab) for the sheds shall be fabricated without obstructions in the mounting surface of the profiles of the sheds such as sheathing pipes, sewer pipes and/or lightning conductors.

- The client is responsible for adequate construction of the foundation and any concrete floor in accordance with local laws, the intended use and the general strength calculations of the Kroftman shed.

- The concrete surface must be horizontal, level and cured. For unevennesses higher/deeper than 5mm a watertight connection is not guaranteed.

When mounting with concrete anchors on a floor of prefab concrete slabs

- The concrete surface must be larger than the surface dimensions of the shed according to the Kroftman construction drawings.

- The client is responsible for a correct construction (such as foundation and slab thickness) of the precast concrete floor in accordance with local legislation, the intended use and the general strength calculations of the Kroftman shed.

- The mounting surface should be flat (unevenness max. 5mm high/deep) with a maximum slope of 1 cm/m1 in one direction. A concave, convex or skewed surface is not permitted. Because of the plate joints present, delivery with a watertight connection is not possible.

In case of installation with ground pins

- Mounting with soil pins is only permitted for temporary applications on pavement (clinkers, asphalt) where the underlying soil consists of compacted sand, gravel or rubble fraction. The pavement is pre-drilled with ∅30mm.

- The mounting surface should be flat (unevenness max. 5mm high/deep) with a maximum slope of 1cm/m1 in one direction. A concave, convex or skewed surface is not allowed. Delivery with a watertight connection is not possible.

![]() Secure

Secure

website

![]() Euro code

Euro code

compliant

![]() Secure

Secure

payment

![]() Over 12.800

Over 12.800

projects worldwide